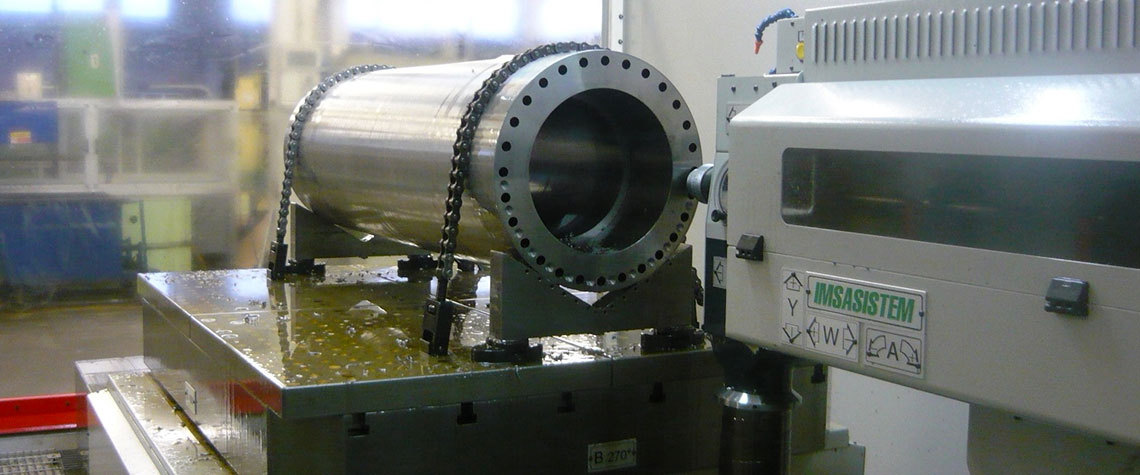

The cutting-edge technology of our machinery allows us to provide our customers with a complete array of supply solutions

Horizontal, crossed and inclined deep drilling

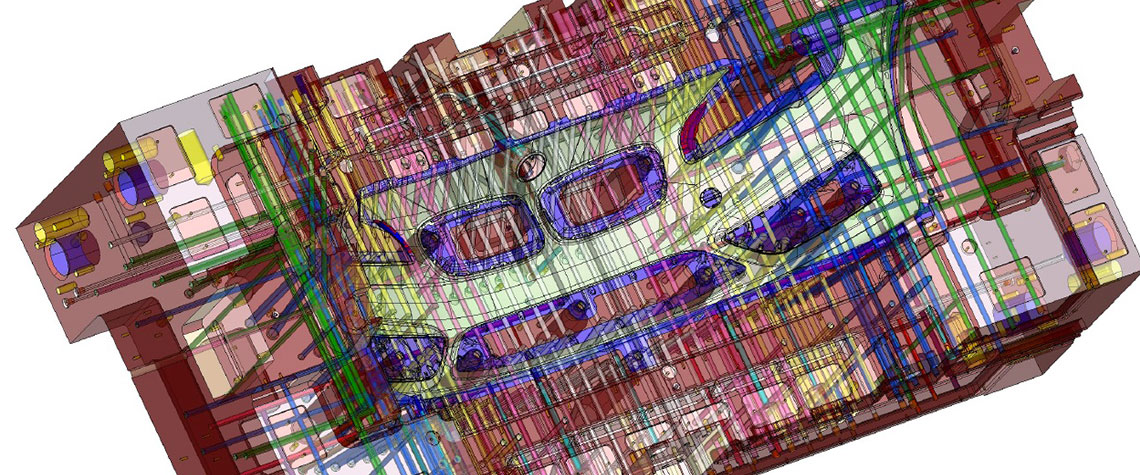

Thanks to this process it is possible to quickly create the most complex cooling circuits with the highest precision standards.

Double inclined drilling is performed without moving the piece at each hole.

This procedure is managed by our CAD CAM software which automatically processes the technical drawing provided by the Customer and identifies all the holes locations. The system then generates the necessary “tool paths” that the machines will have to perform.

Fields of application: moulds, dies, plates, sheets, distributors, drivers and prismatic pieces in general of all sizes.

- Drilling system: gun drilling (traditional or mechanically fixed)

- Number of drilling machines: 5 (IMSA 2000, IMSA 1350, IMSA 1000, IMSA 800, HERBERT)

- Drilling range: from ø3.50 mm to ø44.00 mm

- Max depth holes: 2000 mm for blind holes, 4000 mm for through holes (the maximum depth is related to the hole diameter)

- Max workpiece dimensions: surface 4000 × 3000 mm / maximum weight 6.5 tons.

- Numerical controls: CNC SIEMENS, FANUC, SELCA, HEIDENHAIN